Shaft ISO9001 2021 Standard Carbon Steel CNC Machining Bearing Linear Shaft

Basic Info.

| Appearance Shape | Round |

| Journal Surface Roughness | 0.63-0.16μm |

| Shipping | UPS, DHL, Air |

| Descriptions | High Precision Gear Pump Drive Shaft Made in China |

| Services | OEM ODM Free Sample |

| Delivery Time | 10-25 for Samples; 20-35 for Batch Goods |

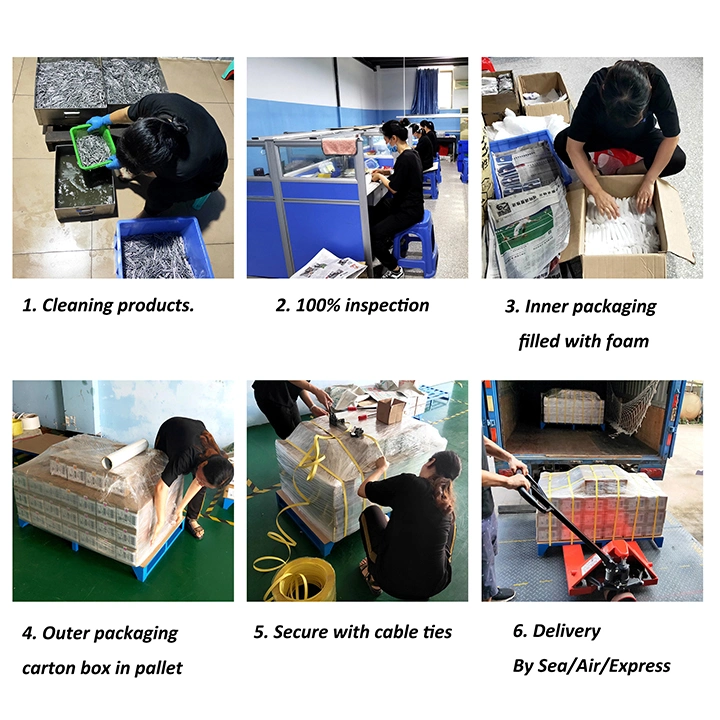

| Transport Package | Polybag+Carton |

| Specification | According to buyer′s drawing |

| Trademark | OEM |

| Origin | Changzhou City, China |

| HS Code | 8483109000 |

| Production Capacity | 500000PCS/Year |

Product Description

Product Description| Business type | Factory/manufacturer |

Service | CNC machining |

| Turning and milling | |

| CNC turning | |

| OEM parts | |

Material | (1) Aluminum:AL 6061-T6,6063,7075-T |

| (2)Stainless steel:303,304,316L,17-4(SUS630) | |

| (3)Steel:4140,Q235,Q345B,20#,45# | |

| (4)Titanium:TA1,TA2/GR2,TA4/GR5,TC4,TC18 | |

| (5)Brass:C36000(HPb62),C37700(HPb59),C26800(H68) | |

| (6)Copper, bronze, magnesium alloy, Delan, POM, acrylic, PC, etc. | |

| Service | OEM/ODM avaliable |

Finish | Sandblasting, anodizing, Blackenning, zinc/Nickl plating, Poland |

| Powder coating, passivation PVD plating titanium, electrogalvanization | |

| Chrome plating, electrophoresis, QPQ | |

| Electrochemical polishing, chrome plating, knurling, laser etching Logo | |

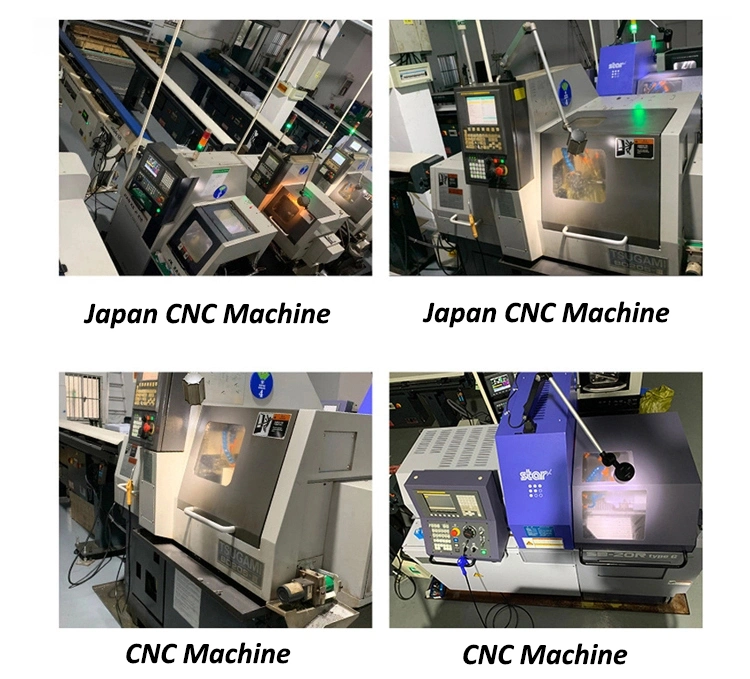

Major equipment | CNC machining center (milling machine), CNC lathe, grinding machine |

| Cylindrical grinding machine, drilling machine, laser cutting machine | |

| Graphic format | STEP, STP, GIS, CAD, PDF, DWG, DXF and other samples |

| Tolerance | +/-0.003mm |

| Surface roughness | Ra0.1~3.2 |

Inspection | Complete testing laboratory with micrometer, optical comparator, caliper vernier, CMM |

| Depth caliper vernier, universal protractor, clock gauge, internal Celsius gauge |

| MATERIAL AVAILABLE | |||||

| Aluminum | Stainless Steel | Brass | Copper | Plastic | Iron |

| AL2024 | SS201 | C22000 | C10100 | POM | Q235 |

| ALA380 | SS301 | C24000 | C11000 | PEEK | Q345B |

| AL5052 | SS303 | C26000 | C12000 | PVC | 1214 / 1215 |

| AL6061 | SS304 | C28000 | C12200 | ABS | 45# |

| AL6063 | SS316 | C35600 | etc. | Nylon | 20# |

| AL6082 | SS416 | C36000 | PP | 4140 / 4130 | |

| AL7075 | etc. | C37000 | Delrin | 12L14 | |

| etc. | etc. | etc. | etc. | ||

SURFACE TREATMENT | |||||

| Aluminum Parts | Stainless Steel Parts | Steel Parts | Brass Parts | ||

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating | ||

| Color Anodized | Passivating | Oxide black | chrome plating | ||

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black | ||

| Chemical Film | Laser engraving | Powder Coated | Powder coated | ||

| Brushing | Electrophoresis black | Heat treatment | Gold plating | ||

| Polishing | Oxide black | Chrome Plating | etc. | ||

| Chroming | etc | etc | |||

| etc | |||||

TOLERANCE | |||||

| The smallest tolerance can reach +/-0.001mm or as per drawing request. | |||||

DRAWING FORMAT | |||||

| PFD | Step | Igs | CAD | Solid | etc |

Changzhou Shinemotor Co.,Ltd located in Changzhou City, Jiangsu Province of China.Mainly specializes in developing, manufacturing and selling all kinds of customized metal and plastic parts. Our factory pass SGS, ISO9001/ ISO9001/ ISO14001 verification, parts can be widely used in the fields of automobile,medical instruments, electronic communications, industrial and consumer applications and so on. We have introduced a series of advanced and high performance production equipment imported from Japan and Taiwan:High precision cnc lathes, 5/6 axis cnc machining centers, plane grinding & centerless grinding machines,stamping machines, wire cut machines, EDM and many other high-precision CNC equipment.Our inspection equipment includes: projector, 2D, 2.5D, CMM, hardness testing machine, tool microscope, etc.

We dedicated to developing and producing kinds of brass, aluminum, steel, stainless steelAnd plastic machining parts, stamping parts, and also mould design and manufacturing.We firmly hold the concept of " customer is the first, honesty is the basic, accrete win-win ". Dedicated to providing you with high-quality products and excellent service!We sincerely look forward to creating a better future by mutually beneficial cooperation with you.

FAQ

1. Are you a factory or a trading company?

A: We are a factory which has been specialized in cnc machining & automatic manufacturing for more than 10 years.2. Where is your factory and how can I visit it?A: Our factory is located in Changzhou city and you can get more detailed information by browsing our website.3. How long can I get some samples for checking and what about the price?

A: Normally samples will be done within 1-2 days (automatic machining parts) or 3-5 day (cnc machining parts).The sample cost depends on all information (size, material, finish, etc.).We will return the sample cost if your order quantity is good.4. How is the warranty of the products quality control?

A: We hold the tightend quality controlling from very begining to the end and aim at 100% error free.5.How to get an accurate quotation?♦ Drawings, photos, detailed sizes or samples of products.♦ Material of products.♦ Ordinary purchasing quantity.♦ Quotation within 1~6 hours